To offer comprehensive service to our clients, we have a manufacturing workshop which allows us to carry out the orders following tailor-made plans. All of our machines are fitted to work on hard metal: for example, precision shafts and ballscrews. The workshop was created in 2001 to broaden our capacities and to establish a specialized production facility

W : Is the most commonly used as a linear balll bearing raceway. It has suitable hardness and is cost effective (Ck55 or Cf53)

WV : Characteristics similar to W type, but resistant to corrosion due to the addition of a chrome layer (Ck55 or Cf53)

WRA : Material used for its resistance to corrosion. Its hardness is medium high ( X90CrMoV18 / W 1.4112 )

WRB : Similar to WRA type, with a lower chemical resistance to corrosion. Less expensive ( X46Cr13 / W 1.4034 )

WH : Used for application requiring low weight or the ability to pass air, fluid or cables in required (Ck60 / W1.1221)

WVH : Characteristics similar to WH type, but resistant to corrosion due to the addition of a chrome layer (Ck60 / W1.1221)

Delivery of precision shafts

Precision shafts are available in standard manufacturing length 6000 +/- 200 mm up to 20 tonnes per delivery

Or Cut to the desired length, with cutting line which allows us to reach a capacity greater than 1000 cuts/day.

Or Machining according to customer drawing, with our dedicated machining workshop adapted to working with induction hardened shafts Machining in Small, medium and big series

| Série | Description | Duretée Mini | Sur stock |

| W | Nuance d’acier : Cf53 Arbres de guidages linéaires trempés par induction et rectifiés h6 | 60 HRc | Ø4 – 100 mm Ø1/4” – 4” |

| WV | Nuance d’acier : Cf53 Arbres de guidages linéaires trempés Chromés par induction et rectifiés h7 | 60 HRc | Ø4 – 100 mm |

| WRB | Nuance d’acier : X46Cr13 Arbres de guidageslinéaires trempés inox 13% par induction et rectifiés h6 | 53 HRc | Ø5 – 60 mm |

| WRA | Nuance d’acier : X90CrMoV18 Arbres de guidages linéaires trempés inox 18% par induction et rectifiés h6 | 55 HRc | Ø5 – 50 mm |

| WH | Nuance d’acier : Ck60 Arbres de guidages linéaires creux trempés par induction et rectifiés h6 | 60 HRc | Ø12 – 80 mm |

| WHV | Nuance d’acier : Ck60 Arbres de guidages linéaires creux chromés trempés par induction et rectifiés h6 | 60 HRc | Ø12 – 80 mm |

| BAC | Nuance d’acier : Ck45 Barres chromées / tiges de vérins- Rectifiés f7 | Non trempé | Ø6 – 80 mm |

| BAX | Nuance d’acier : AISI 304 | Non trempé | Ø12 – 50 mm |

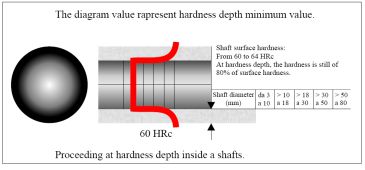

HEAT TREATMENT

Precision shafts are induction hardened; this treatment ensures a uniform surface hardness of HV 697 – HRC 60 both in radial and axial direction. The stainless steels are subjected to a more stringent process to prevent excessive internal stresses, while ensuring a surface hardness of HV 595 – HRC 55.

Obtain information via our form: CLICK HERE

An expert will take care of your request in order to best respond to this product.

Conformément à l’article 43 de la loi ‘Informatique et Libertés’ relative à l’informatique, aux fichiers et aux libertés, vous disposez d’un droit d’accès, de modification, de rectification et de suppression des données qui vous concernent sur simple demande ecrite à commercial@fli-industrie.fr